Dave Mundy

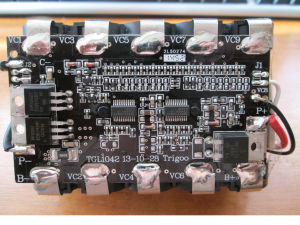

So, (as everyone starts sentences with ‘so’ these days), here’s the scenario. One 36 volt lithium-ion power pack for an extendable hedge cutter and chainsaw, one 36 volt charger for same. What would you expect to find in the casing of the power pack? 10 x 3.6 volt lithium-ion rechargeable cells? Correct. What else? Picture attached! Can anyone guess what that is all about?

(Click on the picture below to see a larger or clearer version of this picture:

Click the “X” button (top right) to close the newly opened picture.)

John Howell

I should think most of it is protection circuitry to prevent discharge to below a certain voltage. If this is allowed to happen and a fast charge is then given that’s when the fireworks start. The monitoring is applied to every cell and probably there is control over the charge rate, you never know what charger Joe public will try and plug in.

Keith Wicks

Li-Ion cells are more demanding than Ni-Cd and NiMH cells. Li-Ion cells may fail if allowed to discharge below a certain voltage, or if overcharged. In batteries, small differences between individual cells can eventually lead to large differences in the charge held after ordinary charging. Hence the use of an occasional long equalising charge for Ni-Cd and NiMH batteries, in which some cells become charged fairly quickly and then radiate further electrical energy supplied as heat. Meanwhile, the weaker ones continue charging and, eventually, all cells in the battery are fully charged.

This technique would damage Li-Ion batteries so, ideally, the cells’ voltages are individually monitored during charging, and each cell’s supply is carefully controlled to avoid the risk of overcharging. Also, the voltages are, ideally, checked during discharge and the supply is made to cut out automatically at a certain low voltage to prevent cell damage.

Sealed lead-acid batteries also suffer if over-discharged, so these, too, often have electronics to monitor the battery voltage and cut off the supply when the battery voltage is low. I had some portable runway lights powered by sealed lead-acid batteries, and I was surprised that these had low-voltage cut-off circuits. It seems that protecting the batteries was deemed more important than ensuring that an aircraft had at least low-level lighting on the runway.

All the monitoring and regulation required by these modern batteries requires lots of electronics (which is amazingly cheap when produced in quantity).

Tony Crake

I bought one of these fancy Dyson “Hoovers on a stick”… Hated it at first but now beginning to love it!

The motor on that is very complicated: each pole is fed with its own power supply – so your lawn machine may have some of that in it as well. Nothing is simple now!

Why were you taking it to pieces I ask?

Dave Mundy

Simples, it won’t charge up! As soon as I put the voltmeter on it the voltage drops to zero! It will cost £69.99 for an exact replacement from Eckman, or £132 to have it re-celled with NiMH cells! The annoying thing is that it took 5 months to get the complete package from EasyLife and I have only used it 10 times at the most!

Keith Wicks

Check the voltages of the individual cells. If you are lucky, you may find that just one is faulty. Replacement cells are readily available and not very expensive, but be sure to replace with exactly the same type. Ideally with the same make of cell.

Dave Mundy

They are welded together so it won’t be easy!

Dave Plowman

The problem is that most of these battery packs have the individual cells connected by welded on strips. Soldering tends to damage them – as it isn’t as quick, so overheats the cell internals.

Keith Wicks

I’ve repaired numerous battery packs (all three main types) and also built 5 complete battery packs from surplus cells without causing damage when soldering. But it is very labour intensive. I’ve had most trouble with glue making it difficult to remove individual cells from some batteries. I use strips of thin steel for joining cells. When removing an old cell, kitchen scissors should be good enough to cut existing strips if you don’t have some small tin snips. Working with a very hot iron will speed the process and help to avoid damage when soldering in a new cell.

Nick Ware

The photo doesn’t give much idea of physical size or show us the cell types, but two things I would suggest, mainly for safety, and to prevent fire risks.

Yes, you can probably re-cell the pack, but I would recommend that whatever size the cells are, you can almost certainly get a ‘tagged’ version of it, and should replace them all, not just the dead one. The tags are spot welded in a fraction of a second, whereas soldering takes longer and a good non-dry joint isn’t easy, and might well cause internal damage.

Presumably, you’ve put your test meter across each cell individually?

Next: if the cells are 18650 types, be aware that these are the most faked batteries out there. Search “fake 18650” on YouTube. You could find yourself buying low capacity or even non-rechargeable AAAs inside the outer casing, marked with absurdly impossible current capacities on the outside.

I’m guessing that the 36V is being reduced to around 15V by the two power transistors on the PCB. If it were not so, the power tool would gradually slow down from the moment you start using it.

Personally, despite being the most have-a-go electronics enthusiast on the planet, I’d opt for the £69 new battery pack option. Likely to be the safest decision you could make.

Dave Mundy

Thanks, that’s the conclusion I came to! Remember the Boeing Dreamliner fires?

Pat Heigham

Some time ago, I sourced replacement cells (sealed lead acid in that case) from: https://cellpacksolutions.co.uk/: they might be able to supply what you need.